| 1. |

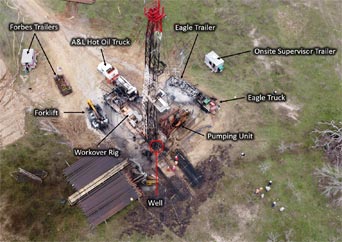

On January 29, 2020, at approximately 3:00 p.m., the Daniel H. Wendland 1-H well (“Wendland 1-H well”), located in Burleson County, Texas and operated by Chesapeake Operating, L.L.C. (Chesapeake), experienced a loss of well control that resulted in a blowout of the well. Oil and gas escaped the well, and within seconds, found an ignition source, resulting in a flash fire in the vicinity of the well that fatally injured three contract workers and seriously injured another. One of the workers, who had been working close to the release point, suffered fatal burn injuries and died at the incident site. Two others suffered serious burn injuries and later died from their injuries. A fourth worker also suffered serious burn injuries but survived. All of the injured personnel were contract workers from either Eagle PCO LLC (Eagle) or CC Forbes Energy Services (Forbes).

At the time of the incident, eleven contractors were working at the Wendland 1-H well site. At the time of the incident, contract workers from Eagle were in the process of installing a new tubing head as part of a workover operation. Workers from Forbes, who provided the workover rig, were near the Wendland 1- H well preparing for their follow-on task of installing tubing in the well. Following the blowout, the ensuing flash fire destroyed the workover rig and several nearby vehicles, resulting in an estimated $1 million in property damage in addition to the fatalities and serious injuries.

|

|

|

True |

|

|

False |

| 2. |

Prior to installing the new tubing head, Chesapeake’s contractors pumped 50 barrels (bbls) of 10-pound-per-gallon (ppg) brine with the intent of providing hydrostatic pressure against the formation. The contractors also relied on open surface valves as mechanical well control barriers. The intended well control barriers were ineffective in preventing the loss of well control and subsequent blowout. Industry guidance does not provide reliable well control methods for completed wells in ________________ reservoirs. Further, existing regulations do not require the implementation and maintenance of well control for onshore oil and gas operations. |

|

|

Over-pressured |

|

|

Under-pressured |

| 3. |

The CSB determined that the cause of the Wendland 1-H well blowout was the ____________________________________. Insufficient industry guidance regarding well control for completed wells in under pressured reservoirs contributed to the blowout, resulting in ineffective well control practices for these types of wells. The attempted well control barriers were ineffective, resulting in the release of hydrocarbons that ignited upon finding an ignition source. |

|

|

the lack of well planning regarding the implementation of well control |

|

|

employees smoking at the job site |

| 4. |

The CSB also determined that ________________________, resulting in three fatal injuries and one serious injury. The absence of regulations governing onshore oil and gas operations contributed to the incident, resulting in the failure to both effectively control hazardous energy and implement essential risk assessments that could have prevented this incident. |

|

|

ineffective ignition source management contributed to the fire |

|

|

lack of no smoking sign |

| 5. |

Which one of the following three options has been recommended by the CSB regarding the regulatory changes?

- OPTION1: Apply the Process Safety Management (PSM) standard (29CFR1910.119) to the drilling of oil and gas wells; or

- OPTION2: Apply the Process Safety Management (PSM) standard (29CFR1910.119) to the drilling of oil and gas wells as in OPTION 1, and make the necessary modifications to customize it to oil and gas drilling operations; or

- OPTION 3: Develop a new standard with a safety management system framework similar to PSM that applies only to the drilling of onshore oil and gas wells that includes but is not limited to the following:

|

|

|

Option 1 and 2 |

|

|

Option 3 |

|

|

Options 1, 2, and 3 |

| 6. |

Figure 3 shows:

|

|

|

Tornado pattern in the great planes, mid-section and northeast of the US |

|

|

Oil and gas wells across the US. Oil wells are shown by green dots, gas wells by red dots, and combination oil and gas by yellow dots. |

| 7. |

Figure 6 shows: |

|

|

A typical ground water aquifer diagram |

|

|

Graphical representation of reservoir pressure characterization |

| 8. |

Figured 7 shows : |

|

|

Schematic showing over pressured reservoir versus under pressured reservoir and why artificial lift is needed in under pressured reservoir to produce oil |

|

|

Water well pumping water from an aquifer. |

| 9. |

Figure 17 shows and describes: The installation crew from Eagle was in the process of torquing the bolts attaching the tubing head to the top casing flange when the well began releasing oil and gas through the open stabbing valve and casing valves. One worker described feeling drops of oil followed by an “explosion” as the oil and gas released from the well. Shortly after the blowout began, the hydrocarbons ignited, engulfing the area around the well in flames. |

|

|

True |

|

|

False |

| 10. |

In Figure 23, Before the Wendland 1-H oil blowout to the surface occurred, workers at the location ______________________. Workers from Eagle were in the process of bolting up the wellhead when the release suddenly transitioned to a large volume of oil and gas. Figure 23 depicts the final stage leading to the blowout and the oil and gas blowout event. |

|

|

reported seeing gas venting from the well |

|

|

did not notice anything out of ordinary. |

| 11. |

The increase in shut-in pressure following the incident indicated that a change in reservoir conditions occurred. Based on the lack of the ability to continuously monitor reservoir conditions and the lack of available information on offset fracking operations, the CSB was unable to determine which of the above reasons for the change, or which combination of reasons, caused the increase in reservoir pressures.

|

|

|

True |

|

|

False |

| 12. |

The CSB concludes that the well blowout occurred as a result of both a loss of fluid over balance and a change in the reservoir conditions, allowing oil and gas to flow to the surface.

|

|

|

True |

|

|

False |

| 13. |

At the time of the blowout, a mixture of flammable hydrocarbons (oil and gas) was released from the well. Due to the pressure from the blowout, the flammable hydrocarbons were released rapidly, forming a vapor cloud, which found an ignition source (Fig 29). Multiple potential ignition sources were identified in the vicinity of the open wellbore.

Which one of the following could have been a source of ignition?

- Static electricity

- Workover rig

- Hot oil truck

- Eagle truck

- Diesel-powered generator on Eagle trailer

- Forklift

- Hand tools

- Electric hydraulic pump (power pack) with extension cord

- Handheld controller for the torque wrench

|

|

|

a, b, c |

|

|

a, d, i |

|

|

All of above |

| 14. |

The conclusion and findings on this case are:

- Based on shut-in pressures observed before and after the incident, the well blowout occurred as a result of both a loss of fluid over balance and a change in the reservoir conditions, allowing oil and gas to flow to the surface.

- A review of the well history, as recommended by APIRP 59, would have revealed past instances where the Wend land 1-H well could flow oil during a workover. Such recognition may have led to heightened awareness of the potential for well control problems and earlier action taken to maintain well control.

- Chesapeake did not provide written operating or contingency procedures for establishing and maintaining well control. Had Chesapeake and its contractors performed well planning in accordance with API RP 59, an operating procedure describing the instructions for establishing and maintaining well control would have been prepared and posted for use by contractors performing the workover operations.

- Chesapeake failed to provide effective well control guidance, and Chesapeake’s contractors failed to maintain an effective hydrostatic barrier because Chesapeake’s Barrier Policy did not incorporate appropriate methods for maintaining ahydrostatic barrier for a completed well in an under pressured reservoir.

- The use of open surface valves and stabbing valves as a well control barrier is not effective since it (1) is a mitigative control actuated after the release begins and (2) increases the risks to workers in the event of a release by creating a flammable vapor cloud around them with potential ignition sources nearby.

- Present API guidance for well control involving completed wells in under pressured reservoirs is not adequate for the implementation of an effective hydrostatic barrier. Had more robust guidance been presented inAPIRP59, Chesapeake may have instituted more effective well control practices, potentially preventing the incident from occurring.

- Working in the presence of gas during work over operations was a common practice. This practice may have been normalized as a result of API RP 59 language that allows operators to consider flow potential rather than stipulate the recommendation for a two-barrier-to-flow system, and that APIRP59 language regarding the consideration of a two-barriers-to-flow system does not provide adequate guidance to companies operating under pressured wells.

- Chesapeake’s contractors neither evaluated the potential classified locations nor adequately controlled the siting of ignition sources that were in proximity to the open wellbore resulting in the ignition of the flammable gas mixture following the blowout of the well. Had Chesapeake’s contractors assessed the classified areas and the associated siting of potential ignition sources, the flammable gases released during the blowout could have been prevented from igniting, and the incident could have been prevented.

- OSHA currently exempts oil and gas well servicing activities from its Control of Hazardous Energy standard. Had more defined OSHA direction to oil and gas companies been in place such as including oil and gas drilling, well servicing, production, and workover operations in OSHA’s Control of Hazardous Energy standard Chesapeake and its contractors may have taken greater measures to ensure positive well control was maintained throughout its operation, thereby preventing the incident from occurring.

- Had Chesapeake been required to maintain Process Safety Information (PSI), utilized that PSI to evaluate the hazards (working over an open well venting flammable gas to atmosphere in the presence of multiple ignition sources) of the work over, and utilized that hazard evaluation to write detailed specific procedures to conduct all work over and servicing operations, the incident may not have occurred.

- While the Pryor Trust incident was a result of drilling operations, which is not the same as the work over operations that were ongoing during the Wend land incident, it underscores the need for federal regulations for the onshore oil and gas industry. A performance standard, similar to the OSHA PSM standard, would have required Chesapeake and its contractors to develop policies and procedures that could have prevented the incident.

- An industry-specific federal standard for the oil and gas industry, incorporating the lessons learned and information gathered from SEPs and the CSB’s investigation report on the Pryor Trust Fatal Gas Well Blowout and Fire and this investigation report, is necessary.

|

|

|

True |

|

|

False |

| 15. |

To prevent future chemical incidents, and in the interest of driving chemical safety excellence to protect communities, workers, and the environment, the CSB urges companies to review these key lessons:

- To successfully execute well control, proper well planning is required. Industry guidance recommends gathering well information, evaluating potential hazards based on that information, and creating operating procedures and contingency plans to address those hazards. Companies should incorporate well planning, based on industry guidance, into their well control policies and procedures.

- Despite having substantial industry guidance regarding how companies should conduct well control, industry guidance is lacking regarding specific well control methods for completed wells in under pressured reservoirs. Companies that operate these types of wells need to be aware of this gap and use necessary resources, such as other recognized technical literature, such as Well Control for Completions and Interventions by H.Crumpton, when creating well control policies and procedures for work overs.

- All phases of well operations, including work overs, can involve potential ignition sources, some of which cannot be eliminated. To mitigate the potential for the ignition of flammable material at well sites, companies should incorporate ignition source risk assessments into their policies and adhere to industry guidance and regulations on ignition source placement, including the use of properly rated equipment.

|

|

|

True |

|

|

False |

|